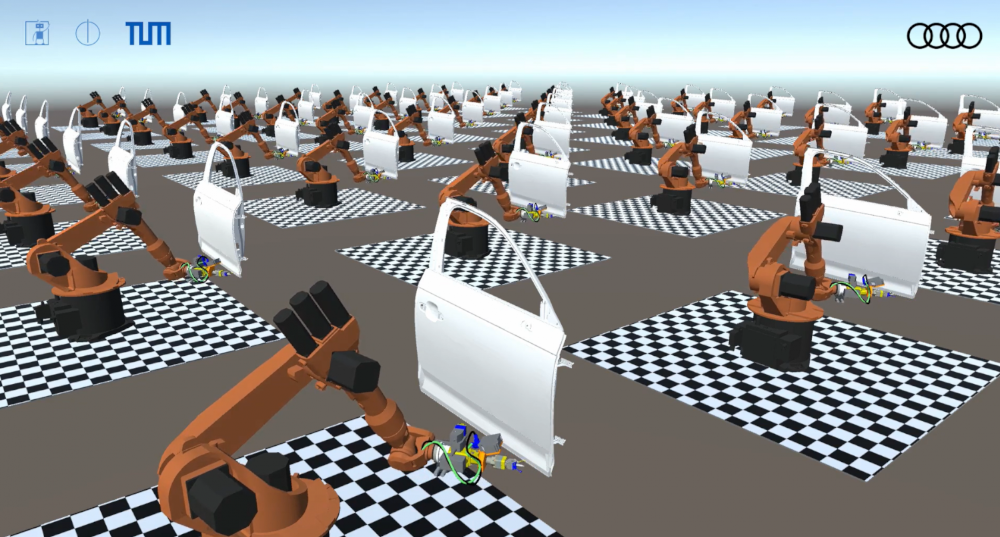

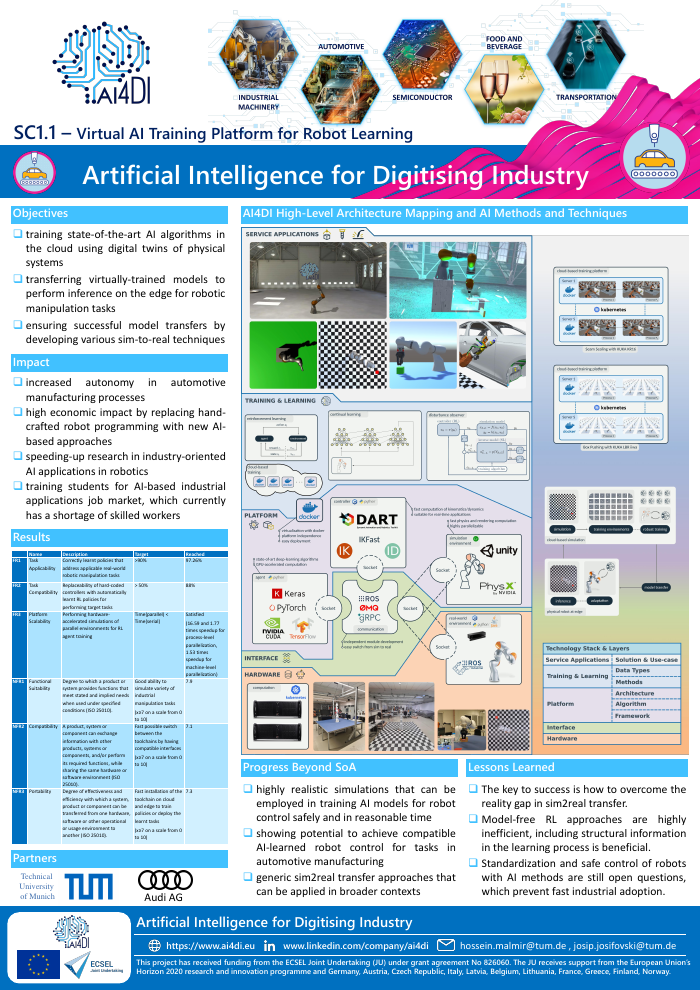

Current state-of-the-art approaches in Artificial Intelligence (AI) require large amounts of training data to solve industrial challenges. It is worth mentioning that the performance is highly dependent on the size and quality of the training data. While large datasets of real-world training data exist or can easily be generated for some problem domains, in robotics data is particularly hard to acquire due to the needed effort, time and hardware resources, or due to safety precautions.

To this end, the TUM team under the AI4DI project is developing simulation environments in which AI agents can be virtually-trained to control robots to execute industry-relevant challenges. To provide a high level of realism in simulated physics and rendering, we use high-end physics simulators and game development engines. In the video, we demonstrate how the virtual environment can be used to train an AI agent for solving a robotic manipulation task using reinforcement learning.

The benefits of fast and safe training in simulation come with the drawback of limited transferability of the simulation-trained AI agents to control real robots. This is still a major challenge due to the mismatch between the simulation and the real-world environment. In the next step of our research, we are working on approaches that can reduce the effects of the so-called reality gap and improve the transferability to real robots.